Precision Steel Manufacturing Corporation is committed to providing an exceptional customer experience. Whether it’s a single part order or a multiple service request, we are proud to specialize in a broad range of services through our manufacturing processes. We’re ready to work with you. Give us a call at (540) 985-8963, send us an e-mail at sales@nullprecisionsteelmfg.com or visit our “RFQ Form” page for more information.

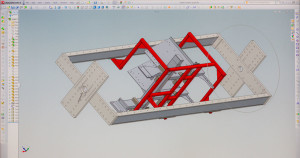

Need help designing a product? From initial concepts to reverse engineering, our skilled engineering staff uses AutoCAD and SolidWorks to easily transform a concept into reality by designing and solid modeling fabricated products.

Working on a prototype? The design process is a critical step to identify design flaws and manufacturing efficiencies. We work closely with our customers throughout the various stages of the prototype development process to ensure success.

Running low on capacity or need parts cut? Our state-of-the-art machines cut, punch, and saw quickly, and hold close tolerances. Internal processes of nesting and batch cutting result in cost savings for our customers.

Forming, bending, and braking —we can do it all. Our fabrication department includes several press brakes, rollers and a pipe bender to handle the most complicated designs.

From thin gauge to thick plate, we specialize in the fitting and welding of a wide range of products. Our manual welding processes include GMAW on steel and aluminum, FCAW on steel and GTAW on steel, stainless steel and aluminum. Our robotic welding processes include GMAW and FCAW on steel. Our certifications are to AWS D1.1 Structural Welding Code – Steel and AWS D1.2 Structural Welding Code – Aluminum.

With a custom media blast booth and parts washing bay, we can transform raw products into finished parts that can withstand the most severe elements. Two large on-site booths are equipped and ready to wet paint a variety of industrial finishes.

Never run out of the parts that you need. We specialize in helping companies keep their items in stock. From Kanban to Just-In-Time (JIT), we cover demand through effective inventory management resulting in reduced customer inventory costs.